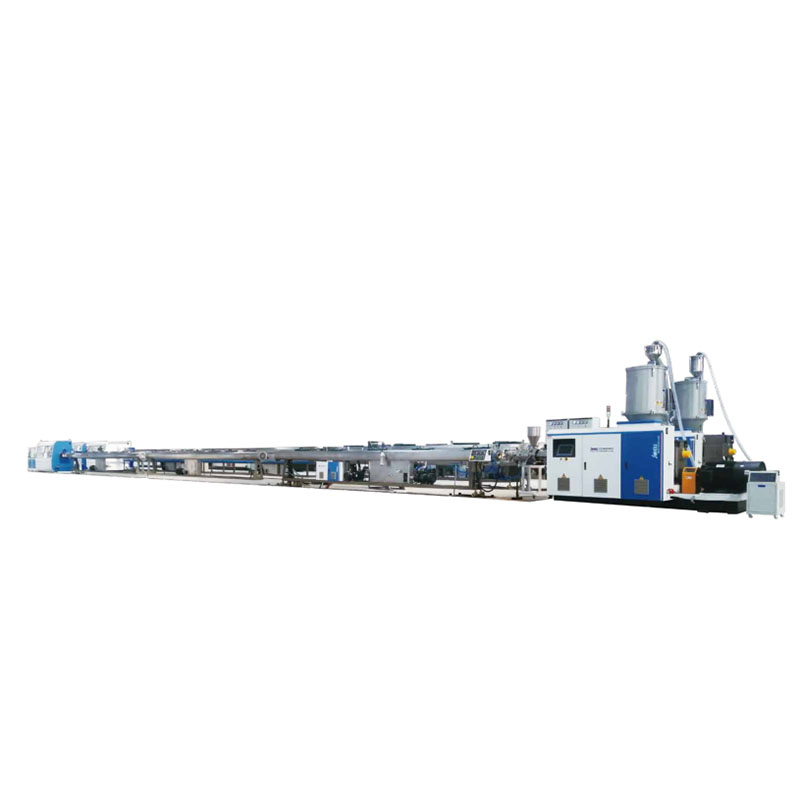

High-speed Energy-saving HDPE Pipe Extrusion Line

Main Technical Parameter

Performance & Zvakanakira

Kambani yedu ichangoburwa tsvagiridzo uye kuvandudza kwesimba-rekuchengetedza yakakwira-kumhanya mutsara wekugadzira, wakakodzera yakakwirira-kumhanya polyolefin pombi extrusion. 35% kuchengetedza kwesimba uye 1x kuwedzera kwekuita basa rekugadzira. Kunyanya kugadzirwa 38-40 L/D screw chimiro uye yekudyisa slot barrel inoita iyo yakanyunguduka extrusion uye plasticizing mhedzisiro ivandudzwe zvakanyanya. Yakakwira-torque, yakakwirira-simba magiya mabhokisi anovimbisa kushanda kwakagadzikana kwemidziyo. Extrusion molds uye saizi yemaoko anotora yakanyanya dhizaini dhizaini. Iyo PLC inosiyana frequency control vacuum tank, servo-inotyairwa yakawanda-track tirakita, uye yakakwira-kumhanya chip-shoma cutter ine mita yekudzora uremu system. Iyo pombi extrusion uremu yakanyatsojeka.

HDPE pombi pombi inochinjika yepurasitiki yakagadzirwa ne thermoplastic high-density polyethylene inoshandiswa zvakanyanya kune yakaderera-tembiricha fluid uye gasi kutamisa. Munguva pfupi yapfuura, mapaipi eHDPE akawana kushandiswa kwawo kukuru kwekutakura mvura inonwiwa, tsvina ine ngozi, magasi akasiyana-siyana, slurry, mvura yemoto, mvura yemvura, nezvimwewo. Iyo yakasimba mamolecular bond yeHDPE pombi zvinhu zvinobatsira kuti ishandise kune yakakwirira-kudzvinyirira mapaipi. Mapombi epolyethylene ane nhoroondo refu uye yakasarudzika yebasa regasi, oiri, migodhi, mvura, uye mamwe maindasitiri. Nekuda kwehuremu hwayo hwakadzikira uye yakakwira corrosion kuramba, iyo HDPE pombi indasitiri iri kukura zvakanyanya. Mugore ra1953, Karl Ziegler naErhard Holzkamp vakawana high-density polyethene (HDPE). HDPE mapaipi anogona kushanda zvinogutsa muhupamhi tembiricha siyana -2200 F kusvika +1800 F. Zvisinei, kushandiswa HDPE Mapaipi haatauri kana tembiricha yemvura inodarika 1220 F (500 C).

Mapaipi eHDPE anogadzirwa nepolymerization ye ethylene, ne-chigadzirwa chemafuta. Zvakasiyana-siyana zvekuwedzera (stabilizers, fillers, plasticizers, softeners, lubricant, colorants, flame retardants, blowing agents, crosslinking agents, ultraviolet degradable additives, etc.) zvinowedzerwa kuburitsa pombi yekupedzisira yeHDPE uye zvinhu. Kureba kwepombi yeHDPE kunogadzirwa nekudziisa iyo HDPE resin. Iyo inobva yawedzerwa kuburikidza nekufa, iyo inosarudza hupamhi hwepombi. Ukobvu hwePipe wall hunotarwa nemusanganiswa wesaizi yekufa, kumhanya kwescuru, uye kumhanya kwetirakita yekudhonza. Kazhinji, 3-5% kabhoni dema inowedzerwa kuHDPE kuti iite kuti UV isarambe, inoshandura mapaipi eHDPE kuita dema muruvara. Mamwe mavara akasiyana anowanikwa asi kazhinji haawanzo kushandiswa. Pombi yeHDPE ine ruvara kana mitsetse inowanzoita 90-95% zvinhu zvitema, apo tambo ine ruvara inopiwa pa5% yekunze.